Scalable analytics for machine builders

Your customers want insight, not raw machine data.

We help you define what to measure and scale analytics across customers, without turning analytics into a custom software product.

- Machines generate more data than ever

- Connectivity is largely solved

- Customers want insight, not raw data

- Analytics starts as a project add-on

- Dashboards differ per customer

What we see:

The reality for modern OEMs regarding data

Most machine builders we speak with are facing the same paradox: their machiness generate terabytes of data, yet they struggle to extract consistent value from it. Over time, this leads to fragmented dashboards and unclear KPI definitions.

- Clear agreement on what to measure

- KPIs tied to service and operational decisions

- Small, standardized core KPI set

- Room for customer-specific extensions

- Open data foundations, no tool lock-in

What’s required:

The foundations of scalable OEM analytics

Scalable OEM analytics is not achieved by adding more dashboards or tools. It starts with establishing a shared foundation that allows insights to be reused, compared, and extended across customers. If you want analytics to scale beyond individual projects, these fundamentals must be in place.

Roadmap to scalable OEM Analytics

A practical path from fragmented dashboards to repeatable insights, without turning analytics into a custom project per customer.

1. Clarify decisions & scope

Before collecting more data or building dashboards, align on the metrics that truly matter across customers.

2. Define a core KPI model

Agree on a small KPI set and definitions that work across most customers and machine fleet.

3. Build the data foundation

Make machine data accesible, strucutred, and usable long-term, independent of dashboards or platforms.

4. Deliver decision-ready dashboards

Build dashboards as an outcome of the KPI model: consistent, comparable and reusable across customers.

5. Extend where it adds value

Allow customer-specific extensions and selective AI solutions without breaking core KPI logic or comparability.

KPIs that OEMs can standardize responsibly

Not every KPI should be standardized and not every machine needs full OEE. Below are examples of KPIs that often make sense for OEMs when measurement foundations are in place.

Core KPIs (often Phase 1):

These KPIs focus on machine behavior and availability, making them suitable for standardization across customers.

Availability

Shows when a machine is able to run versus when it is not. Availability is usually the first KPI that can be defined and standardized across customers.

Downtime duration & causes

Explains how long machines are unavailable and why. Structured downtime causes enable consistent analysis and meaningful prioritization.

Machine Utilization Rate (MUR)

Indicates how often machines are actually used relative to their potential. Utilization adds context to both performance and capacity discussions.

Extended KPIs (context-dependent):

These KPIs add value once core definitions are stable and consistent.

Overall Equipment Effectiveness (OEE)

Combines availability, performance, and quality into a single metric. OEE becomes valuable once loss definitions and measurement logic are agreed.

Mean Time Between Failures (MTBF)

Measures the average time between failures to assess reliability. MTBF is meaningful when failure events are consistently defined and recorded.

Operational Machine Energy Consumption

Tracks energy usage in relation to runtime, machine states, or output. Energy KPIs gain value when sufficient, reliable operational context is available across machines and time.

What this looks like in practice:

Strategic Fleet Dashboard

- Standarized KPI's

- Consistent and comparable

- Focused on availability & downtime

How StriData works

Most digital iniatives fail not because of technology, but because organizations move too quickly to solutions. Our approach is deliberatly structured to create clarity first, only then technology is apllied where it adds value.

1. Business Strategy First

Align goals, service responsibilities, and customer expectations before defining KPIs.

2. Data infrastructure

Design a clear, scalable data structure that organizes machine data for consistent, reusable analytics.

3. Decision-ready insights

Only then build dashboards and analytics that support service and operational decisions throughout the organization.

What makes this approach different:

We don't:

- Start with dashboards or reports

- Apply generic KPI or OEE templates

- Treat analytics as a one-off project

- Lock OEMs into tools or platforms

We do:

- Start from decisions and responsibilities

- Standardize only what truly scales

- Respect machine and customer differences

- Build on open, reusable data foundations

How StriData works

Most digital iniatives fail not because of technology, but because organizations move too quickly to solotuions. Our approach is deliberatly structured to create clarity first, only then we technoloy is apllied where it adds value.

“We are very grateful for the partnership with StriData and their willingness to ensure the customer’s needs.”

Oriol Miarnau, Automation Engineer @ TMI

Use Case

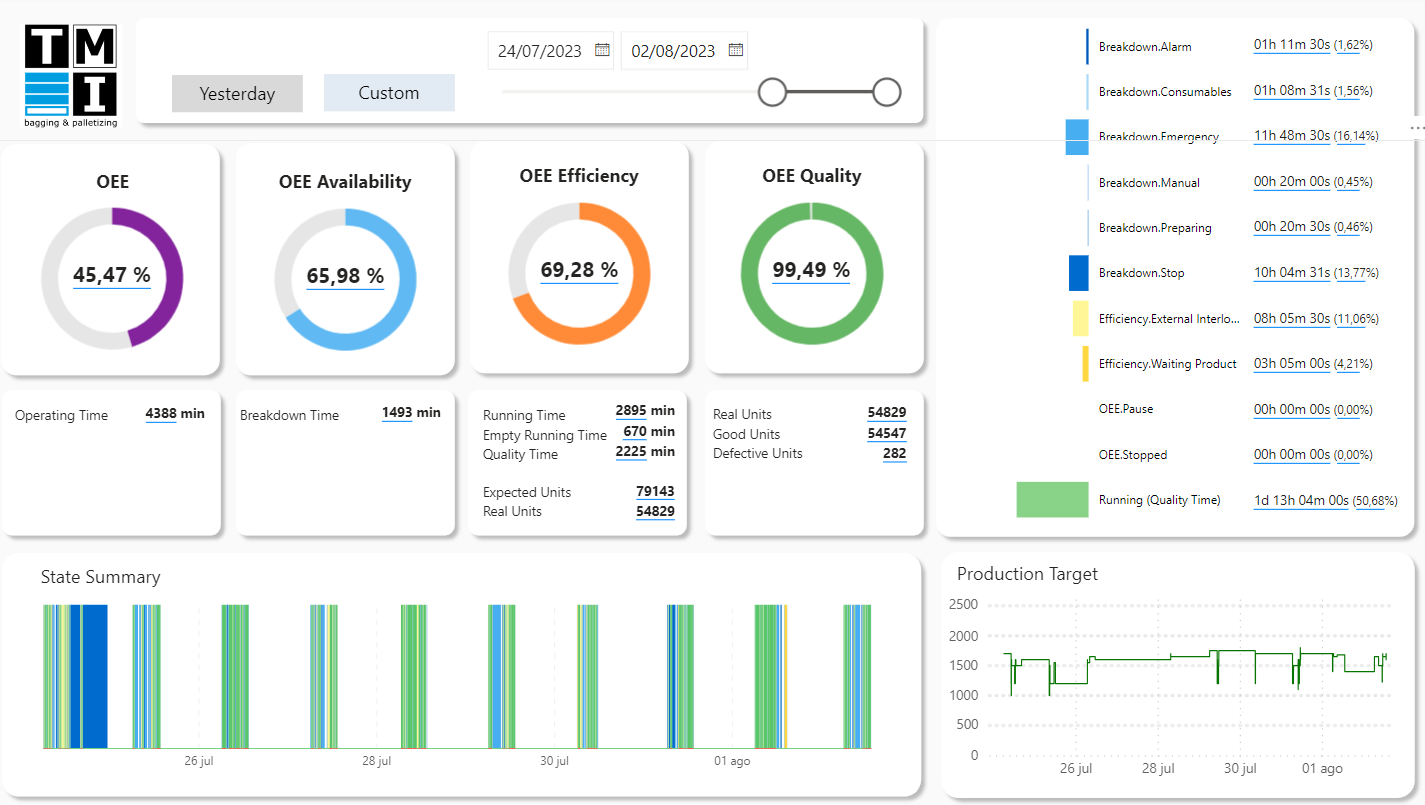

How TMI improved efficiency with StriData's analytics tool.

After implementing StriData's machine analytics tool, TMI were able to improve their overall equipment effectiveness (OEE), reduce downtime significantly and share machine data instantly with their customers.

Resources

Insights for machine builders

Business Intelligence tools are widely used in industrial environments, but they are often discussed as if one tool could cover every use case. In practice, industrial data brings very different requirements depending on whether the goal is monitoring, analysis, or decision support. This article gives an overview of commonly used BI and visualization tools in […]

IXON Cloud welcomes StriData as a TechnologyAlliance Partner to further support advanced machine analytics. Both parties see a rising demand for integrations with AWS, Azure and BI-tools. StriData solutions combine the possibilities of IXON Cloud with these cloud computing services to enable IXON customers to combine live and historical data analytics from multiple sources and […]

How StriData works

Most digital iniatives fail not because of technology, but because organizations move too quickly to solotuions. Our approach is deliberatly structured to create clarity first, only then we technoloy is apllied where it adds value.

Start with clarity for your machines

If you’re a machine builder dealing with growing data analytics requests or dashboards that don’t scale, we’re happy to explore where clarity can help most.

StriData supports analytics for 1500+ machines, helping machine builders reduce downtime, improve availability, and share insights with their customers.

Martijn van Dijk

Founder & Data Engineer